Thermal Management Use Case

How LHS XTS® controls and balances the temperature and heat transfer in lithium-ion battery packs

Overview

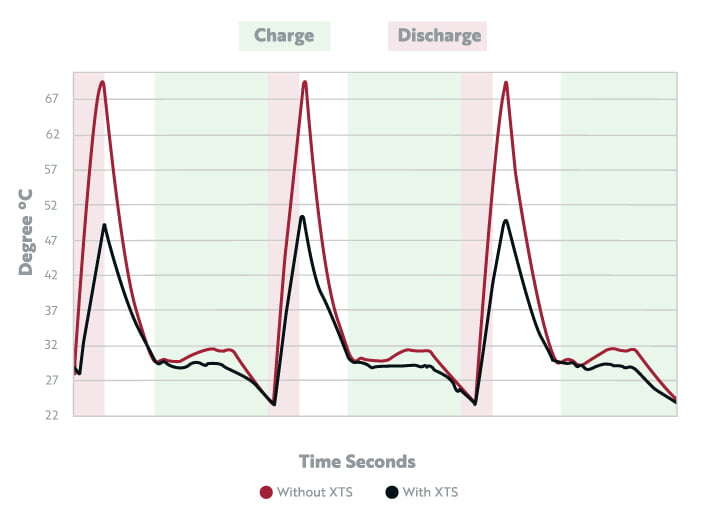

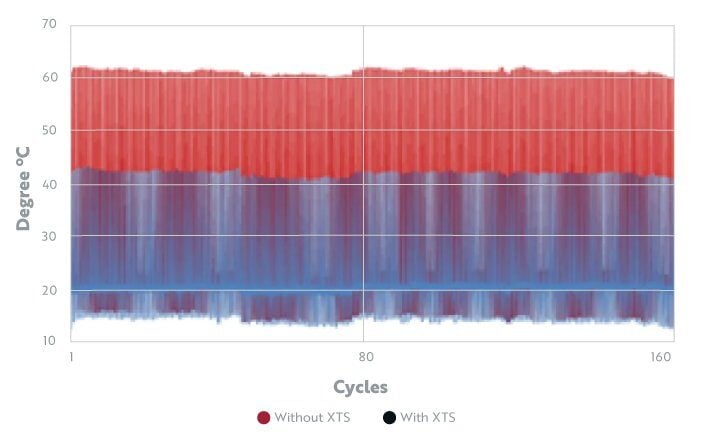

Thermal control of lithium ion battery packs is critical to maximize performance, increase pack life, and reduce safety concerns. Battery packs of all sizes can experience high temperatures over repeated charge and discharge cycles. When temperatures get hot enough this can damage pack components, thermally degrade cells, and ultimately reduce the life of the battery pack. Using LHS’ XTS® product for thermal management will accomplish the following:

- Reduce temperatures at both the cell and pack level

- Improve temperature homogeneity throughout the pack

- Enhance cell and pack life

- Manage heat to reduce cell-to-cell propagation if thermal runaway occurs

Low Cell Surface Temperatures

Approach

When designing a thermal management solution, LHS takes a customized approach to each customer’s battery pack to create an optimized solution that meets application requirements to give the best thermal and safety performance. LHS takes into account the following factors when working with customers:

- Cell type and spacing

- Locations of critical pack components such as BMS’s, wire harnesses, cell connectors/holders

- Operating and environmental conditions such as drive cycles and ambient temperatures

- Available volume for LHS’ XTS passive thermal management material

RELIABLE TEMPERATURE MANAGEMENT

Goal

Design a passive thermal management solution that improves the temperature homogeneity in the battery pack while maintaining a small form factor

METHOD 1

Utilize specific heat capacity of the XTS material rather than latent heat that is used in traditional PCMs

METHOD 2

Contain the material in a conformable pouch to localize thermal runway and ensure maximal cell surface contact while also minimizing parasitic weight

METHOD 3

Contain the aluminum laminate pouch as it acts to spread the heat to access more of the heat capacity of the material in the pouch, while being electrically insulative

Conclusion

Thermal management requires a strategic design approach, specifically for passive systems, which requires a solution to have:

- A minimal impact on the overall weight of the battery system.

- High heat absorption properties with tailorable temperature ranges.

LHS’ thermal management products for Li-ion applications can provides these needs in all-encompassing solution.

LHS works closely with customers to design the right solution for their safety and thermal requirements.

Not sure where to start?

Our experts are specialized in working with you from start to finish.