Thermal Barrier Materials

Module-to-module & cell-to-cell barrier materials

While a range of barrier materials are on the market, none completely address the full complexity of a thermal runaway event.

A successful mitigation strategy must address all the relevant threats to battery pack components.

- Exposure to flame

- Excessive heat transfer

- Forceful ejection of particulates from compromised cells

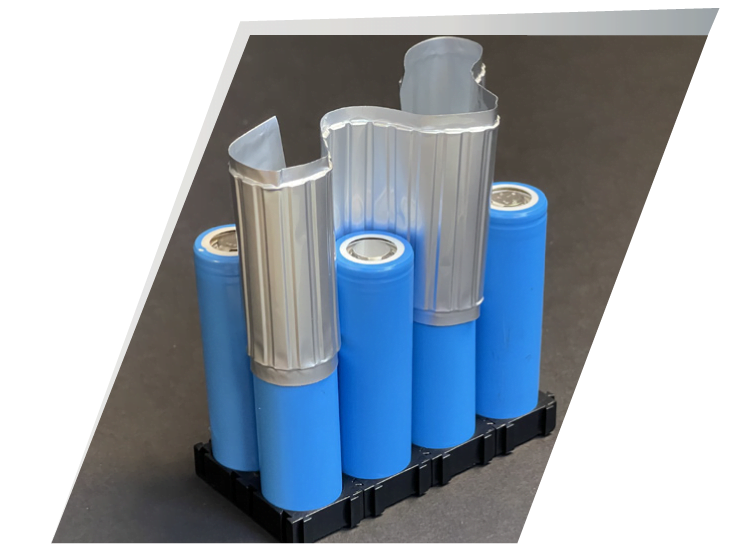

FLAME & THERMAL TRANSFER BARRIER PROPERTIES

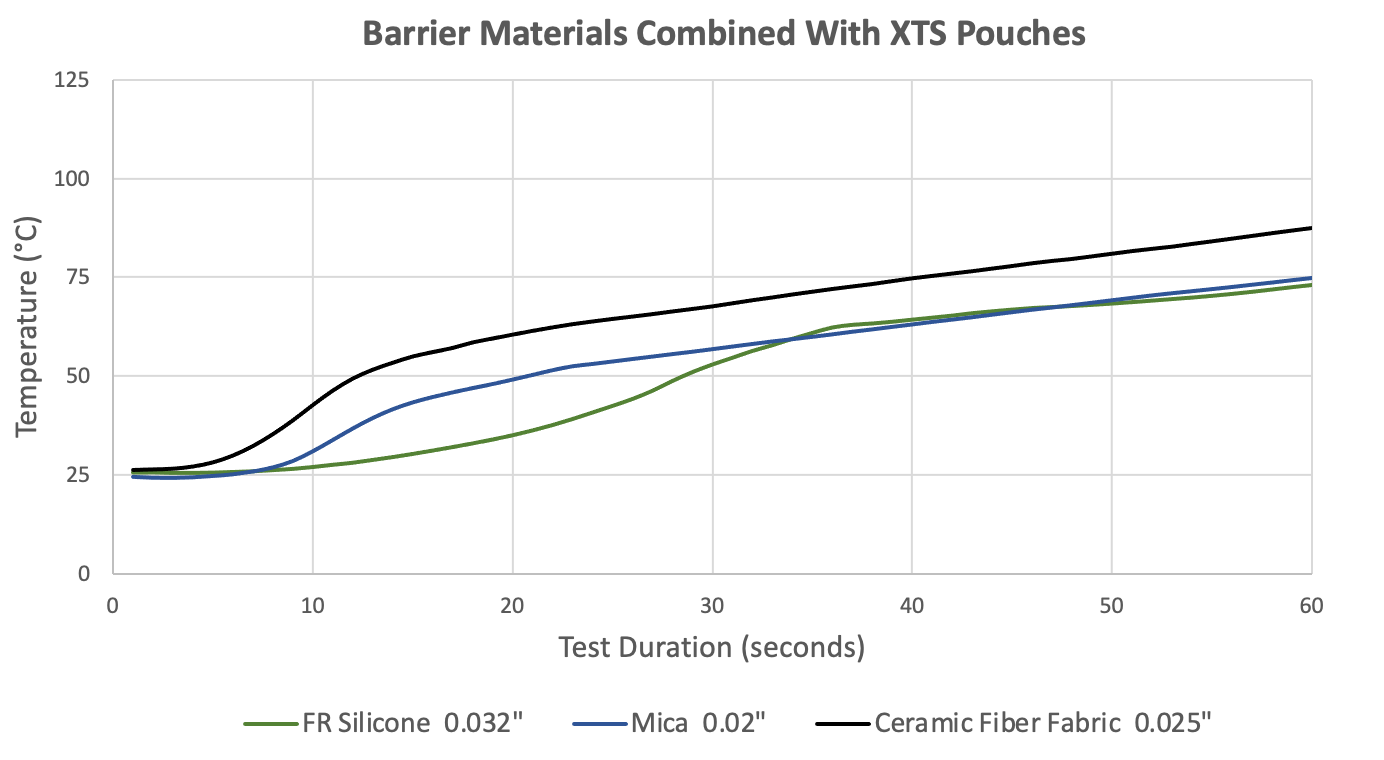

It is necessary that a barrier material restrict thermal transfer between battery components to prevent propagation during a thermal runaway event.

Common barrier materials may withstand exposure to open flame but fail to prevent thermal transfer for any meaningful duration.

XTS POUCH

FR SILICONE

MICA

CERAMIC FIBER FABRIC

XTS Pouches, either alone or in conjunction with a barrier material, are necessary to meaningfully restrict the thermal transfer associated with a runaway event, out-competing common barrier materials.

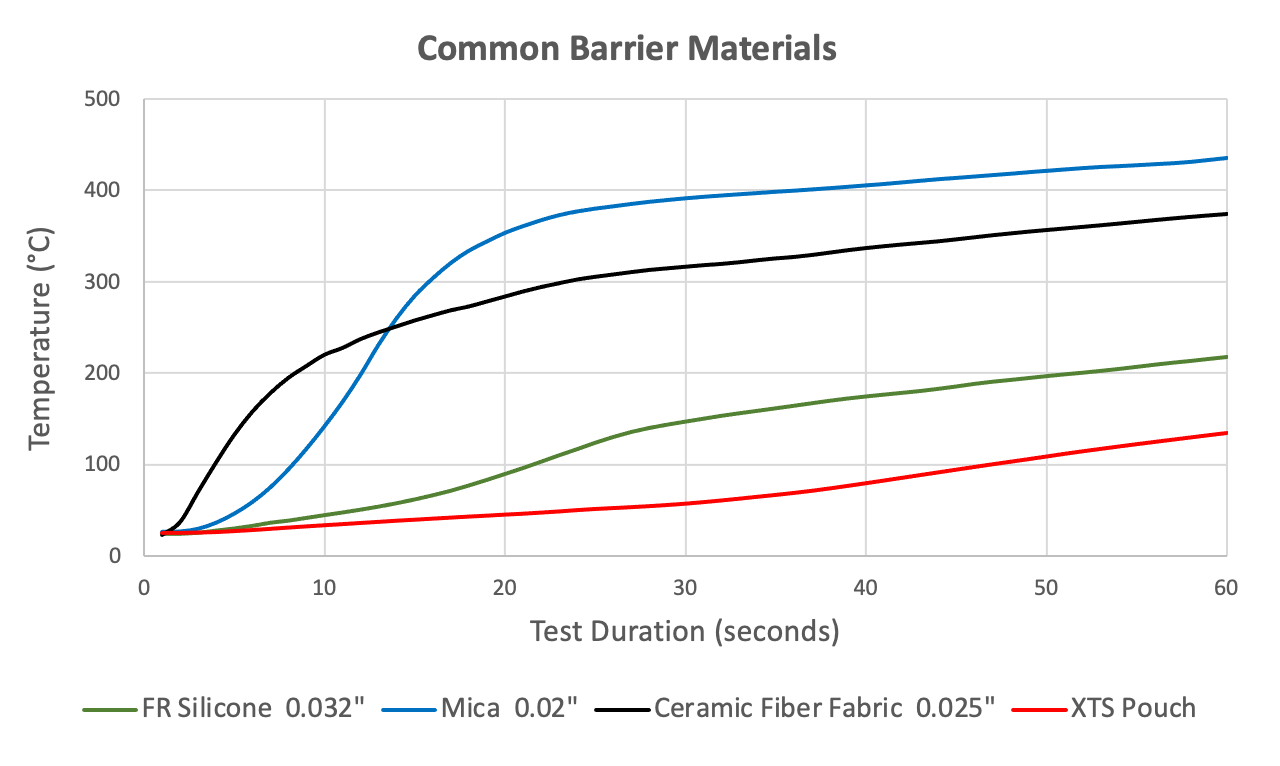

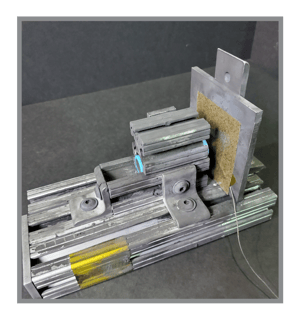

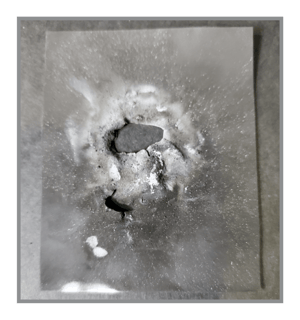

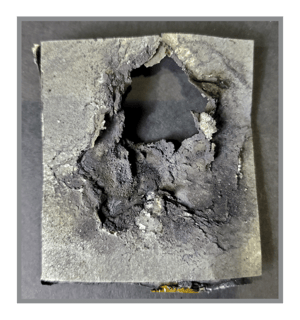

Ejecta Barrier properties

During thermal runaway, a compromised cell will release gas and particulate ejecta at high velocity. A barrier material must be able to withstand this ejecta, which is challenging for most common barrier materials.

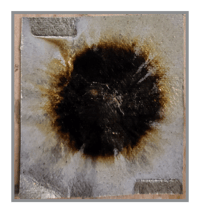

FR SILICONE

MICA

The xts solution

The selection of barrier materials to protect your battery pack from thermal runaway propagation is a vital design consideration. XTS products’ unique ability to capture and remove heat from the system is a necessary component of any complete barrier solution. LHS can provide tailored solutions utilizing XTS alone or in combination with other materials to meet the most rigorous safety requirements.

Not sure where to start?

Our experts are specialized in working with you from start to finish.