Battery Safety USe Case

How LHS XTS® improves battery safety where protection from thermal runway and cell ejecta is a concern or requirement

Overview

A battery powered future demands safety and performance. When heat is left unmanaged it can damage lithium-ion batteries and electronics— thereby decreasing battery life, undermining efficiency, and making batteries unsafe. Thermal runaway occurs in situations when unmanaged heat causes an exponential rise in temperature, often leading to a destructive outcome. There are several factors in controlling thermal runaway, particularly:

- Capturing and converting thermal energy

- Quenching flames

- Controlling Cell Ejecta

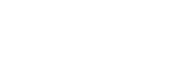

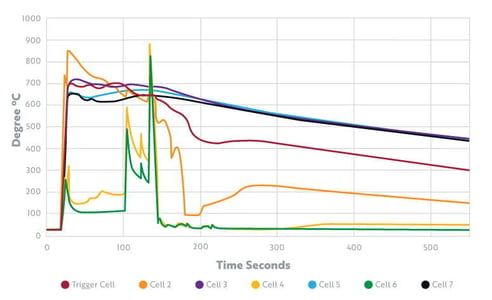

When lithium-ion cells go into thermal runaway, their temperature rapidly increases, vaporizing the electrolyte and increasing pressure until the cell vents. This temperature rise and venting behavior is crucial in designing solutions for controlling thermal runaway.

Challenge

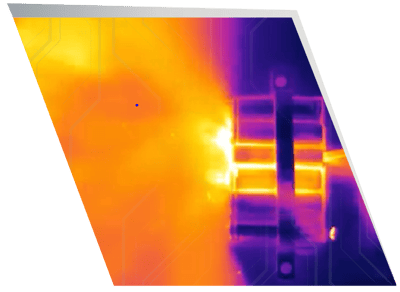

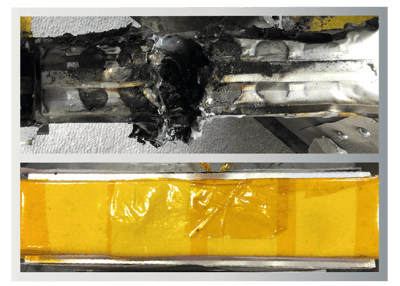

The rapid increase in temperature and pressure of lithium ion cells during thermal runaway can quickly overwhelm safety devices in lithium ion cells (PTCs, CIDs, pressure relief valves, etc) resulting in upwards of 80% of total energy being released through ejecta material:

- Ejection gases and molten materials from the positive or etched rear vents

- Elongation and failure of crimp area, releasing high velocity crimp components and electrode internals

- Rupture of the can sidewalls and ejection of harmful materials from the side

ALL THESE FACTORS CAN PRESENT CATASTROPHIC DAMAGE TO NEARBY PACK COMPONENTS, CELLS, ETC.

Thermal Runaway is Highly Dependent on:

ENERGY & POWER DENSITIES

Cell Chemistry

CELL ARRANGEMENT / PACK STRUCTURE

Cell Manufacturer

All these factors need to be addressed in order to effectively mitigate performance issues or catastrophic damage should thermal runaway occur.

Approach

Design and test a solution for optimal battery safety and protection

FACTOR 1

Capture and convert thermal energy being released

SOLUTION

High latent heat materials (PCMs) were placed at venting points • PCM vaporizes into non-combustible vapor that absorbs substantial amounts of thermal energy

XTS® Protection Comparison

FACTOR 2

Quench and extinguish further flaming in battery pack

SOLUTION

The non-combustible vapor/gas limits oxygen availability in enclosed pack space

Heat & Flame is Released During Thermal Runaway

FACTOR 3

Block or deflect ejecta particles

SOLUTION

- Application of barrier materials at key risk areas for rupture or ejection

- This can include any material capable of withstanding extreme temperatures for a short period of time:

- Metal sheet (aluminum or steel)

- Ceramic plates

- Some thermoplastics or thermoset composites (XTS SC1 Composite)

CONCLUSION

The XTS products by LHS are capable of improving battery safety where thermal runway and cell ejection is a concern

Key Product Benefits of XTS Include:

- Modular design for targeted approach to achieve optimized thermal performance with reduced weight

- Enhanced thermal capacity for cooling behavior during normal pack operations while inhibiting cell-to-cell thermal transfer during abuse events

- Conversion of thermal energy from ejecta from cell(s) rupture for protection of adjacent cell or additional pack components

- Scalable to a diversity of LiB pack architectures

Not sure where to start?

Our experts are specialized in working with you from start to finish.